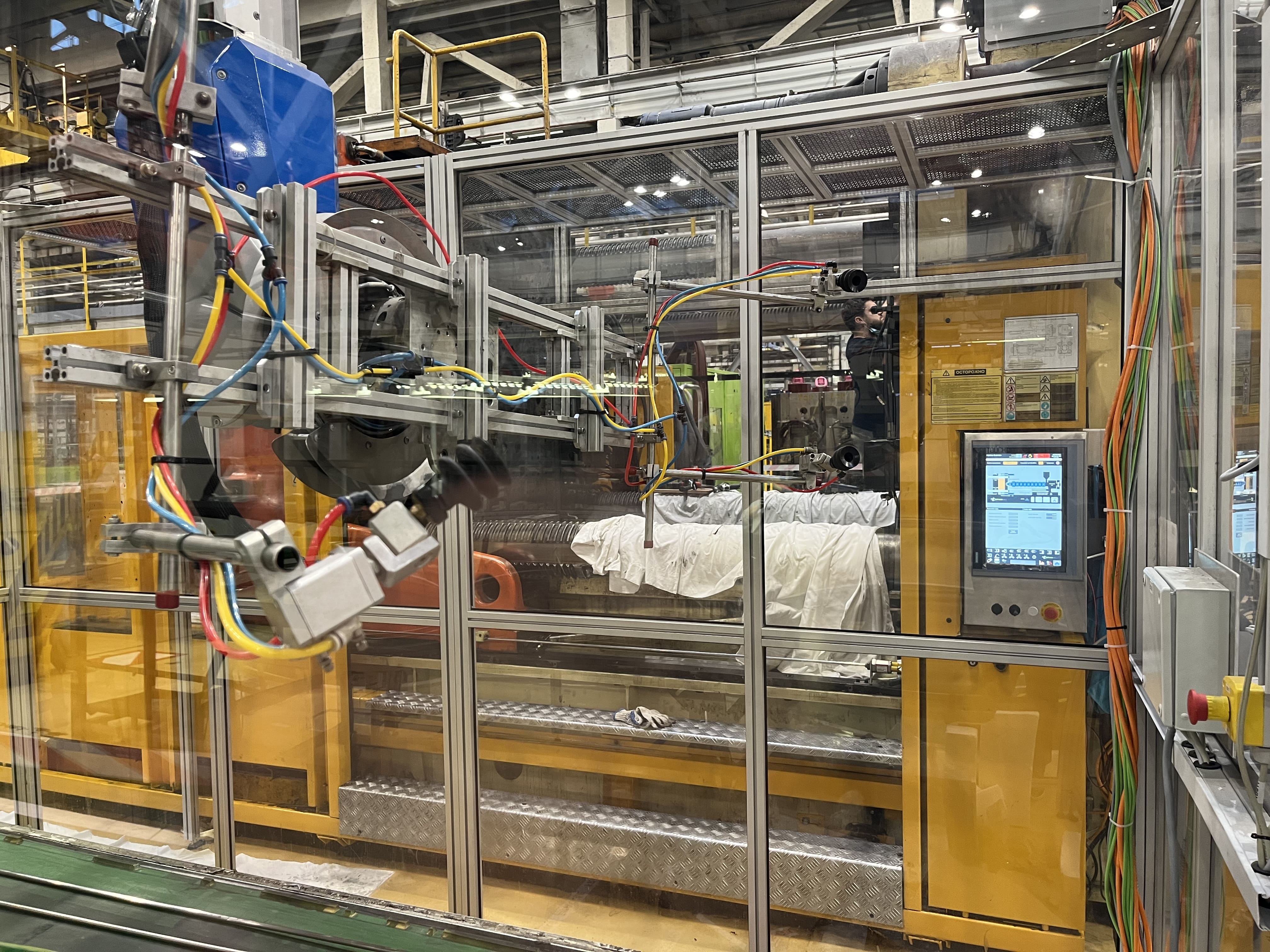

2022 - RETROFIT AVTOVAZ HUSKY 1350/2000

Project Description

Retrofit of 2 horizontal plastic moulding machines (1350 and 2000 tons of clamping force) for producing various products for automotive industry.

Works included complete removal of old computer controls and software and installation of new modern SIEMENS control systems and software including new touch screen HMIs, hydraulics upgrades, mouting of new sensors for hydraulic pressure, implementation of EUROMAP67 interfaces for coordination with external robot, integration of sequential injection controls to replace the need of installing separate devices, installation of new hot runners with 60 temperature zones for mould temperature regulation and rework of electrical wires in the main electrical cabinet.

Share