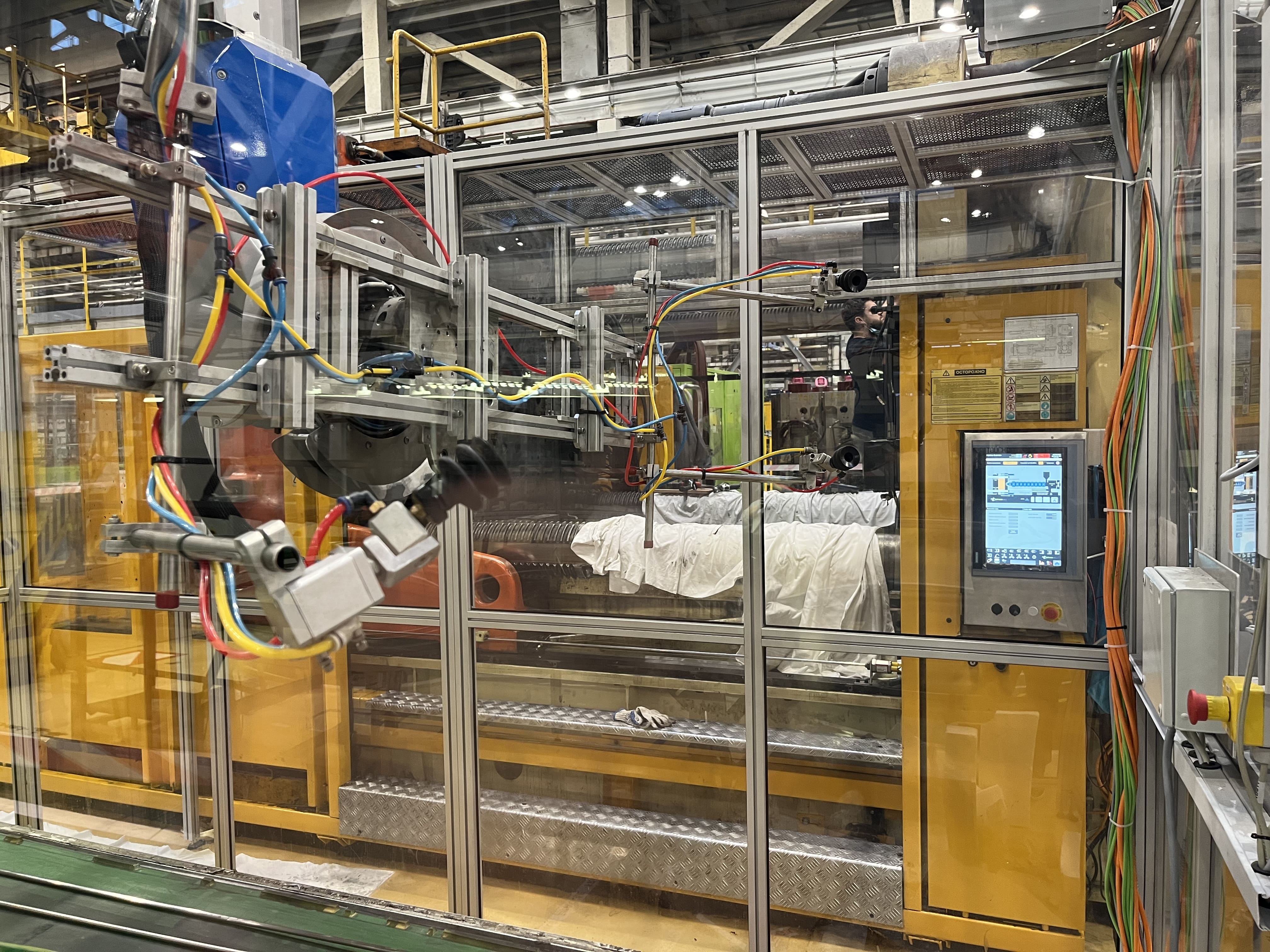

2022 - RETROFIT SOGEFI BATTENFELD 2000

Project Description

Retrofit of vertical plastic moulding machine for producing filters for automotive industry.

Works included complete removal of old computer control and software and installation of new modern SIEMENS control system and software including new touch screen HMI, hydraulics upgrade, mouting of new sensors for hydraulic pressure, installation of new PROFINET absolute encoder for table rotation position measurement, installation of new hot runner for mould temperature regulation and rework of electrical wires in the main electrical cabinet. As an addition we integrated Wittmann water temperature regulators into the system via the serial RS485 protocol.

Share